EDEKA market in new timber construction

Braunschweig-Lamme

Pioneering project for sustainable construction. With TRIQBRIQ’s innovative timber blocks, shorter construction times and greater flexibility are made possible.

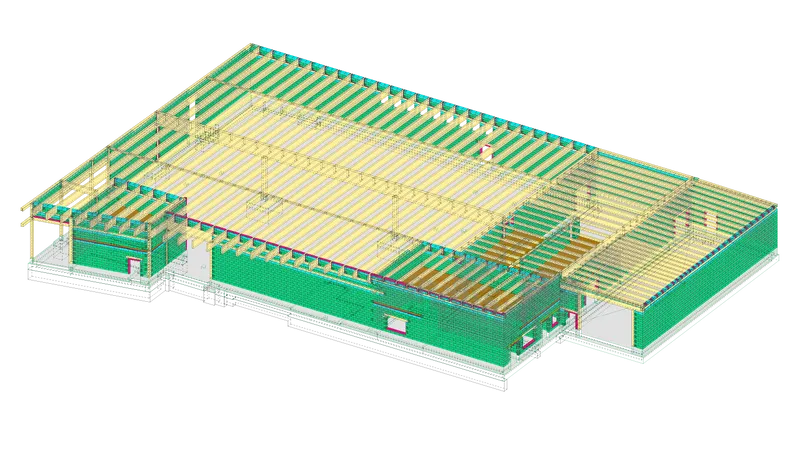

With the construction of a new EDEKA store in Braunschweig-Lamme, a large-scale supermarket has, for the first time, been built entirely using the micro-modular timber construction method of the TRIQBRIQ system. The building is divided into a sales area with a wide-span rafter roof, as well as storage, staff, and delivery zones featuring additional cross-laminated timber floor slabs. With the exception of the reinforced concrete foundation, the entire market has been constructed as a timber building.

The solid timber construction system of Triqbriq AG is based on industrially prefabricated, micro-modular timber blocks, the so-called Briqs. The form-fit connection of the elements creates a load-bearing and stabilizing solid timber wall, assembled on site dry, without glue or metal. Locking is achieved using 20 mm beechwood dowels, which are also demountable.

At the start of the planning process, the existing design, originally conceived in conventional construction, was revised and adapted to the system on the basis of a feasibility study. The structural grid, initially designed as a skeleton structure, could largely be retained and transformed into a solid timber construction. For the execution of window, door, and opening lintels, lintel elements directly installable within the Triqbriq system were also used. The client explicitly requested that as many interior wall surfaces as possible be executed in visible quality, which was integrated into both the architectural and building physics planning.

To ensure a smooth construction process, every single block was already recorded in the 3D model during the planning stage and derived into a detailed wall layout plan including quantities. This level of planning detail was made possible by digital tools and automated subprocesses. In the design phase (work stage 3 according to HOAI), a BIM structural model was created using Autodesk Revit, which was enriched with information and details during the subsequent planning process. From this model, the current volumes and quantities could be read out and verified at any time. To convert the walls from regular wall volumes into individual Triqbriq blocks, a specially developed automation tool was used. In addition to applying the geometric rules of the micro-modular blocks, it still allowed sufficient manual intervention to accommodate special situations.