PARKARENA

Furth im Wald, DE

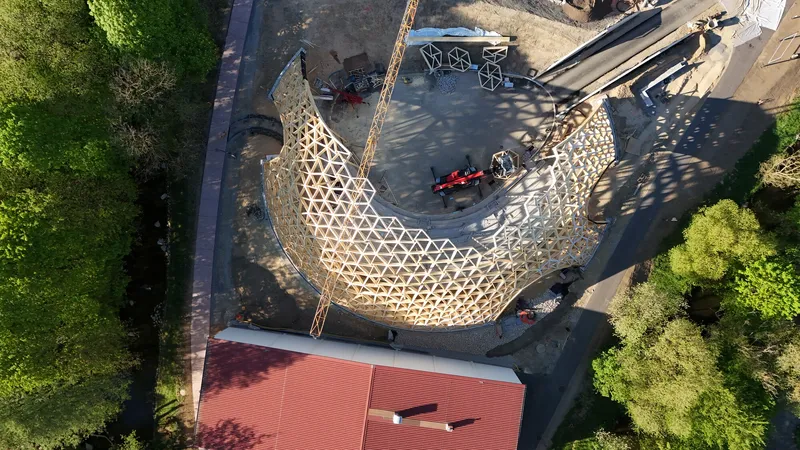

Innovative Gridshell Made from Regional Timber. As centerpiece of the Bavarian State Garden Show 2025, the Parkarena Furth im Wald marks a significant milestone in contemporary timber engineering.

The Parkarena demonstrates how architectural ambition and engineering precision can merge in modern timber construction digitally designed, regionally produced, and executed to the highest technical standards. As a flagship project with supra-regional impact, it will remain a key venue and landmark for the town of Furth im Wald beyond the State Garden Show.

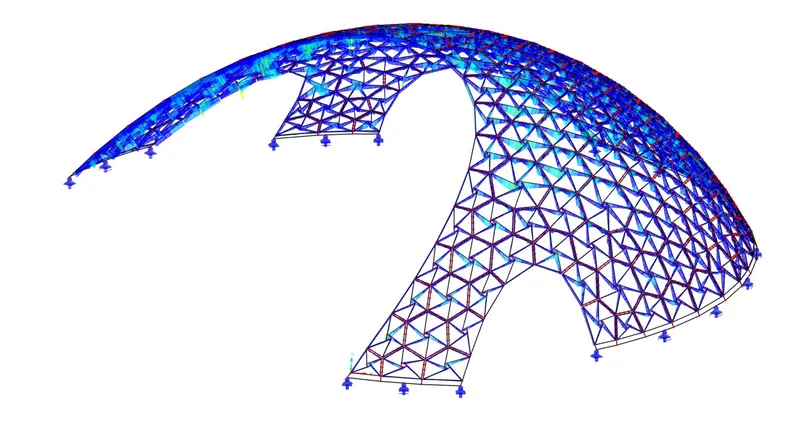

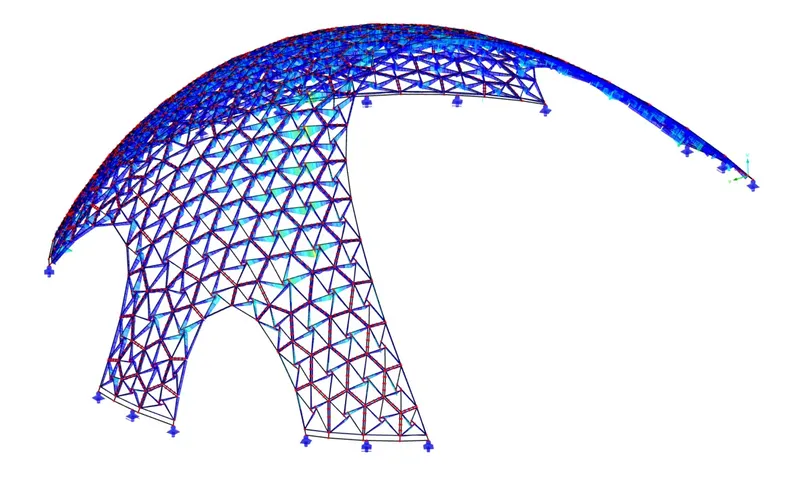

The innovative design enables the construction of a freeform, honeycomb-shaped gridshell, consisting of 168 planar hexagons made of straight glulam elements. A lightweight PVC membrane serves as roof cladding, providing protection for the timber while emphasizing the structure’s airy aesthetic. The shell geometry impresses with its material efficiency and cost-effective production and assembly. The structure achieves a clear span of 40m and a height of 14m with a construction depth of just 40 centimeters. Traditional steel plate connections were largely avoided through a connection system based on design-for-disassembly principles, combining traditional mortise-and-tenon joints with fully threaded screws – reducing emissions by up to 22 tons of CO₂ equivalents. The foundation was also designed for minimal environmental impact. Loads are transferred into load-bearing ground layers at a depth of 4 meters via micropiles. Compared to conventional foundations, this method saved approximately 60 tons of CO₂ equivalents.

At the core of the planning process was a parametric design workflow based on an interdisciplinary geometry model. Each structural element received a unique identifier, allowing automated integration of structural analysis, CAD-to-CAM data generation for nearly 1,900 unique timber parts (including all joints, pre-drillings, and cuts), the design of more than 400 individual laser-cut steel components for the footpoints, and the creation of detailed assembly and execution drawings for each hexagon.

The timber used for the gridshell was sourced from Furth im Wald’s municipal forest and regionally processed into glulam. Prefabrication of the hexagonal elements took place at a local timber construction firm, and with a transport distance of just five kilometers, on-site assembly was completed in only two weeks – almost entirely free-standing and without temporary scaffolding.